Choosing the right thickness for galvanized corrugated sheets plays a critical role in ensuring durability and performance. Thicker sheets handle heavier loads and resist harsh weather better, while thinner ones suit lighter applications. You must evaluate factors to consider, such as the intended use, environmental conditions, and structural needs, to make an informed decision.

Understanding Gauge and Thickness

What Is Gauge in Galvanized Sheets?

Gauge refers to the thickness of a galvanized sheet. It is a standardized measurement system used to describe how thick or thin the material is. A lower gauge number means a thicker sheet, while a higher gauge number indicates a thinner one. For example, a 16-gauge sheet is thicker than a 22-gauge sheet. Understanding gauge helps you choose the right material for your project, whether it involves roofing, siding, or structural applications.

How Is Gauge Measured?

You measure gauge using a specific scale that corresponds to the sheet's thickness in inches or millimeters. Manufacturers often use tools like micrometers or calipers to ensure accuracy. For instance, a 20-gauge sheet typically measures 0.0359 inches (0.91 mm) thick. This system allows you to compare different sheets and select the one that meets your requirements. Always check the manufacturer's specifications to confirm the exact thickness.

Common Gauge Ranges and Their Applications

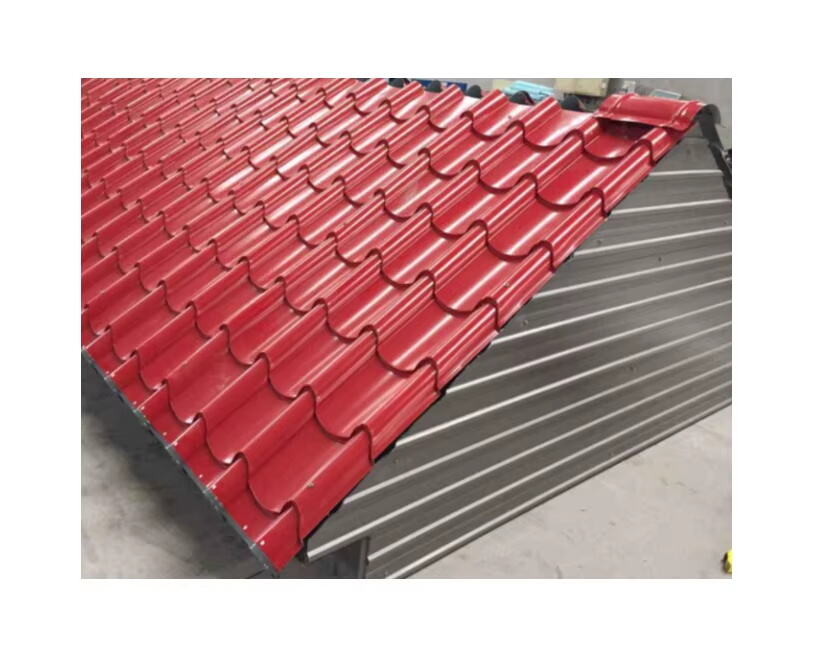

Galvanized sheets come in various gauge ranges, each suited for specific uses. Thicker sheets, such as 14 or 16 gauge, work well for heavy-duty applications like industrial roofing or structural support. Medium gauges, like 18 or 20, are ideal for residential roofing and siding. Thinner sheets, such as 22 or 24 gauge, are lightweight and suitable for decorative purposes or areas with minimal load requirements. When choosing, consider the factors to consider, such as the intended application and environmental conditions.

Factors to Consider When Choosing Thickness

Intended Application and Building Type

Your choice of sheet thickness should align with the purpose of the structure. For example, industrial buildings often require thicker sheets to handle heavy-duty tasks, while residential homes may only need medium or thin sheets for roofing or siding. Think about whether the sheets will be used for walls, roofs, or decorative purposes. Each application has unique requirements, making this one of the most important factors to consider.

Load-Bearing Capacity and Structural Support

The thickness of the sheet directly impacts its ability to bear weight. Thicker sheets provide better support for heavy loads, such as snow or equipment. If your project involves significant weight, prioritize thicker gauges. For lighter structures, thinner sheets may suffice. Always evaluate the load-bearing needs of your building to avoid structural issues.

Weather Resistance and Environmental Conditions

Weather conditions play a major role in determining the right thickness. In areas prone to high winds or storms, thicker sheets offer better resistance. Thin sheets may work in mild climates but could fail under extreme weather. Consider the local climate as one of the critical factors to consider when selecting sheet thickness.

Corrosion Protection and Longevity

Galvanized sheets are designed to resist corrosion, but thicker sheets generally last longer. If your building is in a coastal or humid environment, thicker sheets provide better protection against rust. Longevity is a key factor to consider, especially for structures exposed to harsh conditions.

Cost and Budget Considerations

Thicker sheets cost more due to the additional material. However, they often save money in the long run by reducing maintenance and replacement costs. Balance your budget with the performance needs of your project. While thinner sheets may seem cheaper initially, they might not provide the durability you need.

Ease of Installation and Maintenance

Thinner sheets are lighter and easier to install, making them a good choice for DIY Projects or quick installations. Thicker sheets, while more durable, may require specialized tools and expertise. Consider the time and effort needed for installation and maintenance as part of your decision-making process.

Special Considerations for Extreme Conditions

High Wind and Storm-Prone Areas

In regions with frequent high winds or storms, you need to prioritize thicker galvanized corrugated sheets. Strong winds can cause thinner sheets to bend, warp, or even detach. Thicker sheets provide better resistance to these forces, ensuring your structure remains intact. You should also consider the fastening system. Secure fasteners and proper installation techniques enhance the sheet's ability to withstand extreme weather. Always evaluate the wind load requirements for your area before making a decision.

Heavy Snow Loads and Weight Distribution

If your building is in a snowy region, the weight of accumulated snow can strain your roof. Thicker sheets handle this pressure better, reducing the risk of sagging or collapse. You should also assess the roof's slope. A steeper slope allows snow to slide off more easily, minimizing the load. Pairing thicker sheets with a well-designed support structure ensures your roof can handle heavy snow without issues.

Coastal or High-Humidity Environments

Coastal areas and humid climates expose galvanized sheets to high levels of moisture and salt, which accelerate corrosion. In these conditions, thicker sheets with enhanced galvanization offer better protection. You should also look for sheets with additional coatings or treatments designed for corrosion resistance. Regular maintenance, such as cleaning and inspections, further extends the lifespan of your sheets in these challenging environments.

Choosing the right galvanized sheet thickness requires careful evaluation of application, environment, and cost. Consulting professionals ensures you meet safety standards and local codes. Prioritize durability and performance over short-term savings.

EN

EN