Prehľad sandwich panelov a ich funkcie izolácie

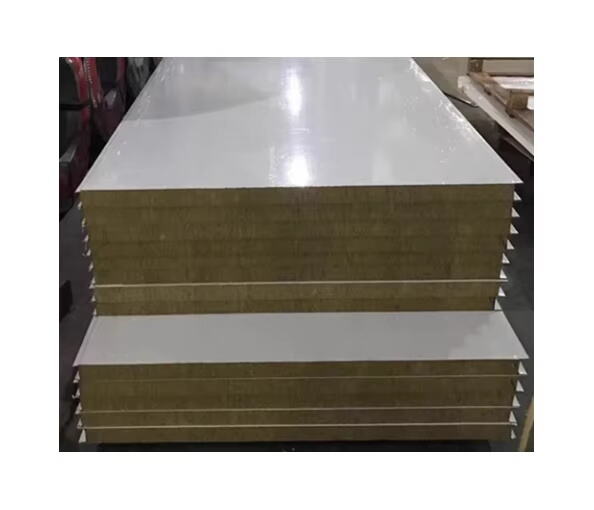

Sandwich panely sú inovatívne kompozitné stavebné materiály navrhnuté na poskytovanie zvýšenej štrukturálnej pevnosti a vynikajúcej tepelnej izolácie. Skladajú sa z dvoch vonkajších vrstiev, známych ako kôže, a vnútorného jдра, a sú technicky vypracované tak, aby poskytovali významné výhody v stavebnej oblasti. Vonkajšie kôže sandwich panelov môžu byť vyrobené z rôznych materiálov, ako je kov, sklovlák alebo plast. Medzi tým je jдро vyrobené z izolačných materiálov, ako je polyisocyanurat (PIR), polystyren (EPS) alebo minerálna vlna. Táto kombinácia umožňuje sandwich panelom sa prispôsobiť rôznym aplikáciám a prostrediam.

Kľúčová funkcia sandwich panelov je poskytnutie tepelnej izolácie pri udržiavaní ľahkej štruktúry. Tieto panely sú osobitne populárne v obchodných aj rezidenciálnych budovách dankom ich efektívnym tepelným vlastnostiam a jednoduchosti montáže. Ponúkaním dokonalého rovnováhu medzi odolnosťou a izoláciou sa sandwich panely stávajú obľubenou voľbou pre architektov a stavebníkov hľadajúcich udržateľné stavebné riešenia. Ne len zvyšujú energetickú účinnosť námornou znížením nákladov na otopenie a chlodenie, ale tiež si zachovávajú svoju štrukturnú výkonnosť v čase, čo ich robí nevyhnutnými v modernej stavebnej praxi. Projekty .

Izolačný mechanizmus sandwich panelov

Rola jadier v izolácii

Jednotka sendvičových panelov hrá dôležitú úlohu v izolácii tým, že bráni prenosu tepla medzi vnútornou a vonkajšou časťou budovy. Táto jednotka efektívne riadi teplotu a energetickú účinnosť. Sú k dispozícii rôzne materiály jednotiek, každý s inou tepelnou výkonosťou. Napríklad materiály ako polyuretan sú navrhnuté tak, aby vydržali vysoké tepelné záťaže a ponúkajú dodatočné výhody, ako je zvuková izolácia. Výskum ukazuje, že polyuretan môže poskytnúť až o 30 % vyššiu tepelnú odolnosť v porovnaní s ostatnými materiálmi jednotiek, čo robí tento materiál veľmi užitočným na úsporu energie.

Ako zachytávanie vzduchu zníži prenos tepla

Jednou z hlavných vlastností sendvič panelov je ich schopnosť uzatvárať vzduch v jadre, čo funguje ako efektívny izolant kvôli nízkej tepelnej vodivosti vzduchu. Tento dizajn účinne minimalizuje prenos tepla, aj pri kolísaní teploty. Táto vlastnosť robí sendvič panely predvolenou voľbou pre stavebníkov, ktorí sa zaoberajú energiou a chcú zlepšiť tepelnú účinnosť. Štúdie ukazujú, že panely s vzduchovo naplnenými priestorami môžu dosiahnuť U-hodnoty až 0,25 W/m²K, čo významne zníži pretek tepla a urobí ich ideálnymi na udržateľné stavebné postupy.

Typy jadier sendvič panelov pre izoláciu

Jadrá z polyuretanu (PU): Vysoká tepelná odolnosť

Jadrná polyuretanová izolácia je veľmi cenena za svoju vynikajúcu tepelnú odolnosť, čo ju robí vhodnou pre rôzne klimatické podmienky a aplikácie. Tieto jadra ponúkajú izolačnú hodnotu až R-7 na palec, čo významne zníži náklady na topenie a chladenie budov. Mnoho výrobcov používa PU jadra v prostrediah, kde sú nevyhnutné prísne energetické normy, pretože splňujú a často presahujú štandardy stanovené organizáciami ako ENERGY STAR. To robí z PU jadier výbornejšiu voľbu pre vysokoefektívnu izoláciu, ktorá optimalizuje energetickú účinnosť.

Rozšírené polystyrenové (EPS) jadra: Dostupná izolácia

Jednoduché polystyrenové (EPS) jádra ponúkajú ekonomické riešenie na teplovú izoláciu, ktoré je populárne v projektoch s obmedzeným rozpočtom. Aj keď majú EPS jádra nižšiu R-hodnotu ako PU jádra, priemerne okolo R-4 na palec, ich preferujú pre bytové a komerčné budovy kvôli ich dostupnosti a ľahkosti. Odvetví spravuje, že sa EPS čoraz viac používa kvôli jeho dobrému odolaniu pred vlhkom a jednoduchej inštalácii, čo robí z neho praktickú voľbu pre projekty so finančnými obmedzeniami.

Minerálna vlna Jádra: Vlastnosti odolné pred požiarom

Jednoduché jadra z minerálnych vln sú známe svojou vynikajúcou odolnosťou proti požiu, čo nie len brání šíreniu plamien, ale tiež zvyšuje bezpečnosť staveb. Tieto jadra ponúkajú aj lepšiu zvukovú izoláciu v porovnaní s inými typmi, čo ich robí ideálnymi pre aplikácie citlivé na šum. Organizácie pre bezpečnosť pred požiarmi často odporúčajú minerálne vlny ako jadra pre komerčné aplikácie, kde je povinnosť dodržiavať požiarne predpisy, čo poskytuje pokoj majiteľom budov v súvislosti s bezpečnosťou ich nemovitostí.

Polyisocyanurat (PIR): Vynikajúca tepelná výkonnosť, energeticky účinný

Jednotky z polyisocyanuratov (PIR) ponúkajú vynikajúcu tepelnú účinnosť a úspory energie, často presahujúce tradičný PU v určitých aplikáciách. S vysokou hodnotou R približne R-6.5 na palec sú jednotky PIR výbornou voľbou pre energeticky účinné stavebné projekty. Osobitne sa uprednostňujú v komerčných priestoroch, kde platia strižnejšie požiadavky na izoláciu. PIR je ekologicky prípustný a prispeva k zníženiu celkového spotrebovania energie, čo z neho robí udržateľnú možnosť pre súčasné stavebné projekty.

Výhody izolácie sendvič panelov

Zabezpečuje úspory energie, tlmenie hluku a pohodlie

Izolácia sendvič panelov významne zvyšuje energetickú účinnosť, čo viede k významným úsporám nákladov na otopenie a klimatizáciu budov. Vdaka zlepšeniu tepelnej odolnosti tieto panely znížia spotrebu energie, poskytujúc dlhodobé finančné výhody pre obytné aj komerčné objekty. Okrem úspor energie ponúkajú sendvič panely vynikajúce schopnosti tlmenia hluku. Ich izolačné vlastnosti pomáhajú znížiť prenos zvuku, vytvárajúc tím klidnejší a pohodlnejší vnútorný prostredok. Štúdie ukazujú, že začlenenie sendvič panelov môže významne zlepšiť hodnotenie energetickej účinnosti, čo sa prejaví znátocnými zníženiami v účtoch za energiu a zároveň zlepšením pohodlia pre obyvateľov.

Použiteľné pre široký spektrum aplikácií, od skladov po bytové budovy

Sandwich panely preukazujú univerzalitu, čo ich robí ideálnymi na široké spektrum stavebných aplikácií, od priemyselných skladov po moderné bytové priestory. Dajú sa prispôsobiť v otázke veľkosti a dokončenia, čím zohľadnia rôzne architektonické návrhy bez újmy pre výkonnosť izolácie. Táto pružnosť spôsobuje, že tieto panely sú čoraz častejšie využívané v stavebnych projektoch, ktoré preferujú materiály, ktoré sú ľahké, ale trvanlivé a energeticky účinné. Podľa priemyselnej údajov existuje narastajúci trend používania sandwich panelov kvôli ich schopnosti kombinovať štrukturálnu kvalitu s estetickou pružnosťou, čím zabezpečujú klientom spoľahlivý výkon v rôznych typoch budov.

Záver

Podľa toho, panely s účinnými jadrami sú kľúčové pre vytváranie energeticky účinných a izolovaných stavebných systémov. Tieto panely umožňujú významné úspory energie, čo zvyšuje tepelnú izolačnú schopnosť budov a zníži náklady na otopenie a chladenie. Ich inštalácia prináša nie len nákladovú účinnosť, ale prispieva aj k lepšiemu pohodli vo rôznych infraštruktúrach.

Výhody, o ktorých sa hovorilo v článku, zdôrazňujú, že tieto panely sú nie len ekonomické, ale dodržiavajú súčasné stavebné normy, čo zabezpečuje bezpečnosť a udržateľnosť. Pre budúce stavebné projekty je integrácia panelov so štúchou strategickým investíciou, ktorá slúbi udržateľnosť, bezpečnosť a účinnosť v dizajne budov. To ich robí ideálnou voľbou pre stavebné spoločnosti, ktoré sa snažia zhodnotiť s modernými životním prostredím a bezpečnostnými normami pri dosahovaní vynikajúcich energetických výkonov.

FAQ

Z čoho sú priečkové panely vyrobené?

Sandwich panely sú tvorené dvomi vonkajšími vrstvami, tzv. kožami, ktoré môžu byť z metálu, sklovlákna alebo plastyk. Vnútorný jadier je zostavený z izolačných materiálov ako polyisocyanurat (PIR), polystyren (EPS) alebo minerálna vlna.

Ako poskytujú sandwich panely izoláciu?

Sandwich panely poskytujú izoláciu prostredníctvom svojho jadra, ktoré uzatvára vzduch a minimalizuje prenos tepla. Použité materiály, ako je polyuretan, sú navrhnuté tak, aby ponúkali vysokú tepelnú odpornost, čo zvyšuje energetickú účinnosť.

Čo sú použitia sandwich panelov?

Sandwich panely sú univerzálne a môžu sa používať v rôznych aplikáciách, ako sú priemyselné skladové priestory, obchodné budovy a rodinné domy. Umožňujú rôznu architektonickú dizajnovú štruktúru, pričom poskytujú izoláciu a štrukturálnu podporu.

Prečo sa považujú sandwich panely za energeticky účinné?

Paprátové panely sa považujú za energeticky účinné, pretože znížia prevod tepla a spotrebu energie, čo viede k úsporám na nákladoch na topenie a chlodenie. Ich izolačné vlastnosti prispevajú k významným zlepšeniam energetickej účinnosti budov.

EN

EN