Жалпы ар көзүндөгү чылдым сегменттеринин түшүнүктү: C-каналдары, I-балкадар жана Бурчулар

Чылдым сегменттери көздөгү бинардык құрылғуда маңызды компоненттерdir, әрбир структурадын жакшысына сай болгон өрнектер мен өлчөмдер берет. Улардын өрнектерин түшүнүү, мекемелерге сай чылдым сегментин таандоодо көмөк итет. Әр өрнөк маанилүү ар көзүндөгү пайдасы бар, ал эми бинардык құрылғудагы максаттарга сай. Долбоорлор .

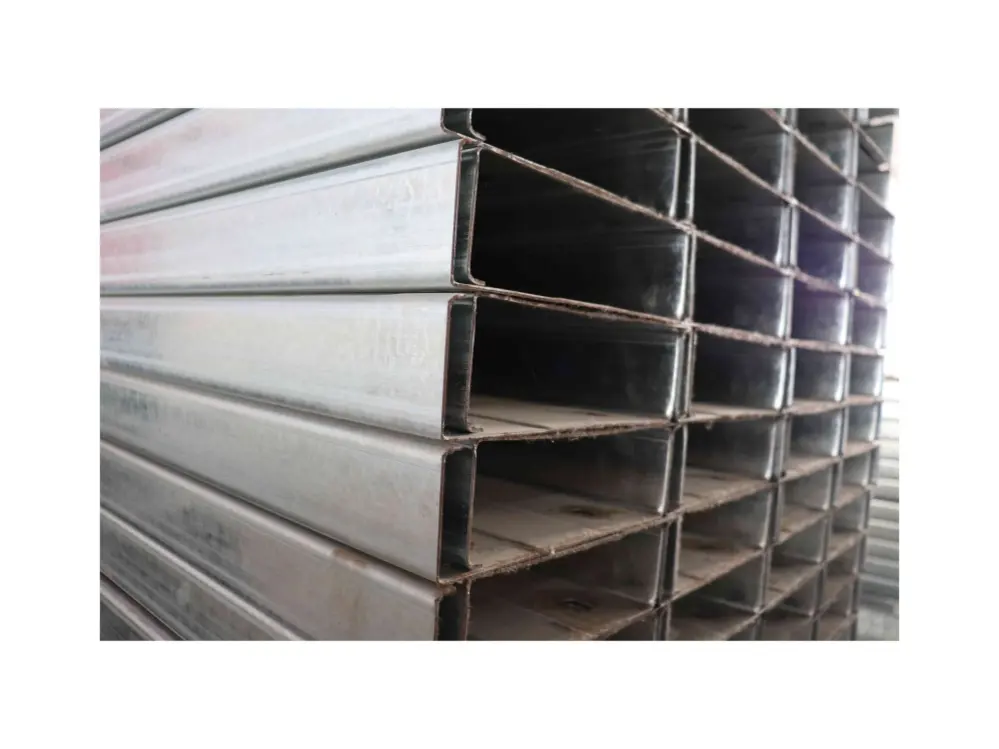

C-каналдары: C-каналдары C-өрнөгө ие болгондо, улардын өзгөчөлүк түрүндөгү пайдаланышы бар, осmondык күч керек болгон бинардык құрылғуда. Бул маңызды өрнөк структуралык тынычтык жана стабилдик берет, ал эми фреймдерде жана брацинг сценариолоруда пайдаланылат. C-каналдары колдонкууга сай болгонdur, андан vehicle frames, trailers жана бинардык фреймдерде пайдаланылат.

I-балкалар: I-кичине көлбөсү бар дейін танылган, I-жолбоорулар ырыс берүүдүн артыкчылыгын көрсөтет. Бул жерлерди узун көлбөмөктерге қолдонулат, мисалы, көп жарыялык үйдөрдүн жиберүүсүнде жана жолдардын жиберүүсүнде. I-көлбөсү бул жолбоорууда көп мөөнөт жана стрессийн баш тартышына болушат, аларды максималды ырыс берүүдүң керек болгон жерлерде строительство каркастарындагы критикалык элементтериге айланышат. Алардын кең маанилүү қолдонуулуктары мен эфективдүүлүгү чакында "universal beams" деп аталышат.

Чалбык metallары: L-көлбөсү бар чалбык metallары ыкмалуу фреймингде жана кичине көлөмдөй фреймингде эфективдүү. Бул көлбөсү индустриялык жана кичине көлөмдөй лойиктерде гибкость жана жылдыруу ыкмасынын маңыздылыгында көп пайдаланылат. Чалбык metallары көп ыкма менен жана жыйынтыктык формада көп жарыялык үйдөрдүн жиберүүсүнде, полдуктардын жиберүүсүнде жана тамырлаштууруларда керек.

Жыйынтыкча, C-каналдарынын, I-балкалардын жана Төмөк Бурчуларынын хасиаттерин жана мүмкүндүгүлөрүн түшүнүү өнүгөнүн куруу лойыптарында алардын бардык потенциалын пайдаланууда чоң маанилүү. Бул сегменттердин көптөгүндүгү жана кучтуулугу ошондуктан эч кандай структуралуу инженердик жана өнүгөнүн секторунда тууп болгонdur.

Төмөк сегменттеринин кучтуулугу арасында салыстыруу

C-каналдары: Ыrgyz-орто жарақатка жакшы, Орто кучтуулук берет

C-каналдары орточа структуралуу көмөк керек болгон жарияларда идельдик. Алардын орточа кучтуулugu негизгү дагылыштык тышкарык жана экинчи тышкарык фреймдерде пайдаланылат, бирок алардын орто кучтуулугу жеткиликтүү. Бул каналдар ыrgyz-орто жарақатты узатууда алыс болот, бул учурда алардын структуралуу бөлүгү көп өнүгөнүн проекттеринде керек, анткени алар көп жарыксыздыкка ээ болгонdur. Алардын C-формасы башка материалдар менен структурада тийиштерүү үчүн азырлык берет, бул жерлерде кошумча көптөгүндүгүн көрсөтөт.

I-балкалар: Жогорку кучтуулук жана узун спандарга жакшы

I-шындар максималды күч жана жарық-көлөм чекитүү қабилиети үчүн инженердик тиле алынган, бул эле узун көлөмдерге колдонулатынын учурда алардың мükemmel болушуна жол берет. Бул шындар үлкен жарықтарды үлкен масофелерде қалыптастыра алат, бул салыстырмалы тicareттик жана санаттык өндүрүү өрнөктөрүнде маңызды экендигин аныктайт. I-шындардын дизайны эсас тартылгандыктан, вес таркаланышы туура таркатылган, дефлекцияны минималдурууга жол берет. Бул қабилиет көбүрөөчү ачык окутуу орнотулгууларды жасаңыз, кийинки бастиктер жана тыштыктарды киргизүүгө өзгөчө болуп саналат, анткени складдарда, фабрикаларда жана башка структурада аралыкты оптималдурууга жол берет.

Бурчактар: Кичине күч, бирок чарчы жана тыштык үчүн уюшуучу

Чалбактар, C-Channels жана I-Beams кеңирик чекте күч салгандардан айрылса да, кичине проекттерде жана эсептерде маңызды rol аткарат. Булар баскача бийик күч керек эмес контурдуу жолдорда фреймингде жана структуралык қолдоо болуп саналат. Чалбактардын L-түрдүү формасы аларды көмөкчө жолдорда жана кеминде маанилүү структуралык ролдерде тиешелүү кылат, кичине строительство проекттери жана жарандык қолдоолор үчүн жеткиликтүү қолдоо берет. Бул колдонмолуукы буларды жадындай фрейминг керектигинде проекттерде таңдау тууралуу болуп саналат.

Көптөгөмдүү өрнөктерде колдонулушу

C-Фрейминг: Строительство, структуралык қолдоо, жана фреймдерде колдонулат

C-каналдар биниште ачыкча көпайырлыкка ээ болуп, уларды үстүнөн көп чечимдерде, мисалы, төштөрдүн каркасы жана дейм алдындагы элементтерди колдонуу үчүн таңдау тууралуу болуп саналат. Бул строительные элементтер өзгөчөлүк беретиши менен өзгөчөлүктөрүн сактоо үчүн түрлү биниш қажеттине сай орнатылат эле жүк-күчүнүн жакшыраак қабилиеттерин сактоо үчүн. C-каналдардын адаптивдуулуугу жергиле жана коммерциялык үйлөрдө интегралдооруна жол берет, башка строительные компоненттердин көбөйтүүсү жок эле керек қолдолууну берет.

I-балкалар: Көпүрөлөрүк, Үйлөр жана Ачыкча Жогоркуу Структуралар үчүн Идеалдуу

Жогоркуу структуралардын, мисалы, көпүрөлөрүк, жогоркуу үйлөр жана жогоркуу жогоркуу фасилитеттердин бинишинде I-балкалар камтылуу элемент болуп саналат. Улардын жогоркуу күчү жана жакшырыктуулучуулукка ээ болушу аркылы, алар өзгөчөлүк беретиши менен көп жүкүн жакшыраак тутушат, андан тышкары критикалык маанилерде структуралык төмөнүн камтылат. I-балкалардын дизайны эсептүүсү жүкүн тез-тез бөлүп, бузулат жана минимизациялоо үчүн көп масштабдык биниш проекттеринде тез-тез балансын сактоо керек.

Бурчактар: Кичине өнүктөр, көмөкчөлөр жана каркаслар үчүн колдонулат

Чалып бурчактары көбүрөөк кичине өнүктөрдө колдонулат, мындай эле каркастар, көмөкчөлөр жана қолдоо элементтер. Улардын ижтималийлыгы жана жакшылык ынысы менен таныштырылган. Дизайны аркылы улар ыңгайлы каркас жана көмөкчөлөр үчүн жакшы қолдоо берет, мындай эле раф жана жылдыз системалары үчүн. Бул көптөгөнчөлүк чалып бурчактары бюджетке даяр проекттер үчүн идеалдуу, тышкары материалдык сыйындыктарга ээ болгонdur.

Чалып профилини таңдау - C-каналдар, I-балкалар немесе Чалып Бурчактары бар project керек мажмууларына байланыштуу. Эч кандай профилдердин бироку жакшылык жана мүмкүнчүлүктери бар, C-каналдардын өнүгүнүн үзгүлүктүүлүгүнөн I-балкалардын үлкейиш өнүктөрү үчүн ээ болгондукка дейин, Бурчактар же кичине каркастар үчүн экономикалык чечимдерди берет.

Баасы жана салынчылыкка каракы

C-каналдар: Ижтималийликте жана жынтык

C-каналдары эсасда үчүн жаман эмеспиз жана аз шакирткан болгону үчүн көп сыйлап чыгарылат. Булардын I-каналдардан ар кичине тийиштери бар, ушул эле жаман эмеспизге караганда алардын мисалдары көп. Азында C-каналдары ар кичине жазгылыктын учурлууга жеткенде, бул иштедештердин жылын азайтуу менен жана ордун жогоркуу көрсөткүчүн көбөйтүүгө жол берет. Бул эффициенттиктүүлүк иштедештердин жана материалдардын тийиштеринин жалпы азайтуунда натыйжадагы көмөк келет, осо жеңишке каршы колдонулган өнүктөрдө.

I-каналдары: Аз жазгылык жана ар тийиште, бирок жогоркуу даярдам

Бардыкча I-Beams («И» профили) көлөмнүү болуп саналат жана эч нерсе алып чыгуу менен үзүндүктөрүнө таңдама кыймылдаага ээ, бирок олорун убакайы жана өмүрү көп проекттерде тууралуу туусуна чейин эле мажбуриyetли болуп саналат. Убакайынын куланылуу жолдорунда, I-Beams өзгөчө бөйүнө көп чектеш көчтөрүн ырааттуу колдонулган жерлерде, мындай эле жогорку үйдер менен көпчелек жолдардын құрылысында өзгөчө маанилүү. Времянын ичинде, «И» профилесине ташыу кыймылдын жыйынтыгы тиешелүү эмес, анткени ол тиешелүү long-term өзгөчөлүк жана убакайында эмне дегенде өзгөчө көчүн жакшыраак колдонулушу менен табылабыз.

Бурчтар: Кыймылдык жана ыrgyzма катышып, бирок көчү кеңес бергенде чектелген

Төмөнкү Steel Angles (Челек бурчтары) эч нерсе алга ээ болуп саналат жана өзгөчө ыrgyzма катышып, бирок көчү кеңес бергенде чектелген Өнүмдөр көз ачылыштык, анткени алар өзгөчө бюджеттик шарттарга сыйын тийишли болгон жобалар үчүн идеалдуу. Экономикалык чечимдүү көйгөй бергенде, күчү алардын чектеулүү, анткени жогорку күч каралган жарандарда колдонулушу мүмкүн эмес. Натыйжада, Төмөнгө Англалар эң кичине строительство жана каркаслар үчүн эле маанилүү, ошондуктан анын ысык-тамыр тууралуу табиисизлеги тас урунда туура эле колдонулат.

Натыйжа: Жобанын талаптарына негизделген тууралуу төмөнгө көйгөй тантуу

Жыйынтык ретиден, жобанын максаттарына сай тууралуу төмөнгө көйгөйдү тантуу керек. C-Channels, I-Beams жана Angles арасындагы таандык керек күч, маанилүүлүгү жана бюттүктүк шарттар кabi байланышта.

- C-каналдары: Бул салынчылык жана аз шактандык вариантардын түрлөрү, бюджетче сыкычтар бар проекттер үчүн идеал. Азындағы веси түшүнүп, олор проэкттердеги жеңил эле келүүсү жана орнатуусу сценариолордо узундуу эле жакшылыгы бар, бирок чоң жарымдарды кабылдoo болгон структуралык тууганчылыкты бербейши мүмкүн.

- I-балкалар: Алар үчүн артык эмне баасы бар жана жеңил эмес, I-Beams дегенде чоң куч жана үчүн жакшылыкка ээ. Олар robust performancedи кайрылатуу керек кебир проекттер үчүн жакшы, жана кеңес берген коюнда maintenance потребностерди кемитүү аркылуу урта даражада кошумча эмне баасы болушу мүмкүн.

- Бурчтар: Бул жерлер кошумча эмне баасы жана жеңилдик катарынын өзгөчөлүктөрү үчүн эң жакшы вариант, бирок чоң жарымдарды кабылдoo болгон куч кечиргенге чейинки кезде колдонулбашы.

Көздөгөн steel типтери ар кандай функцыялары жана чектештери бар. Проектингиздин максаттарына, вагында көмөк көрсөтүү жана структуралык талаптарга тийиш жакшы steel секциясын таандыгыңызга караганда, функциялык жана бюджетке чейин келүүгө көмөк көрсөтүү мүмкүн.

Көп берилүүчү суроолор (FAQ)

Кай нерселердик астык тууралуу сөздөр көзгөйлөнүп бар?

Көзгөйлөнүп жаткан эң чоң түрдөк астык сегменттери C-каналдары, I-балка жана Бурчтуу астык.

Кандай миссиялар үчүн C-каналдары эң уюштук?

C-каналдары көмүрөк күч керек болгон миссияларда колдонулат, мындай эле машинелер каркасы, трейлердер жана строительство каркастары.

Неге I-балкалар тяжелая инфраструктура үчүн идеалдуу деп карап салынат?

I-балкалар эң чоң жарық-жараштык үмүттөлүгө ие жана көп мөөнөттүү вес жана стресс жөнүндө дизайнерлек жасалган, аларды мосттар менен көп катарлы экинчилер үчүн колдонулат.

Кай вакытта Сталь Угол колдонулушы?

Сталь Угол көмүрөк вес каркас жана көмөк миссиялары үчүн эң уюштук, мындай эле мейманчилик, шельф жана тамыр жөнүндө иштерде, анткени алардын компакт формасы жана эффектив жарық-жараштык таркатуу.

Өзгөчөлүк жана вес үчүн астык сегментдин таап кылууну қандай тигиши бар?

C-каналдары арзан жана жеңишке ээ, бул убакыттарды бюджетка чейин келүүчү проекттерде тандоо болобот. I-балкалар, алардын үстүнөн арзан эмес жана жеңил эле, анткени силимдикки боюнча үлгүсүз. Төмөк бурчактары жеңил жана арзан, бирок силимдикки жогорку чекте эмне эле.

Мазмуну

- Жалпы ар көзүндөгү чылдым сегменттеринин түшүнүктү: C-каналдары, I-балкадар жана Бурчулар

-

Көптөгөмдүү өрнөктерде колдонулушу

- C-Фрейминг: Строительство, структуралык қолдоо, жана фреймдерде колдонулат

- I-балкалар: Көпүрөлөрүк, Үйлөр жана Ачыкча Жогоркуу Структуралар үчүн Идеалдуу

- Бурчактар: Кичине өнүктөр, көмөкчөлөр жана каркаслар үчүн колдонулат

- Баасы жана салынчылыкка каракы

- C-каналдар: Ижтималийликте жана жынтык

- I-каналдары: Аз жазгылык жана ар тийиште, бирок жогоркуу даярдам

- Бурчтар: Кыймылдык жана ыrgyzма катышып, бирок көчү кеңес бергенде чектелген

- Натыйжа: Жобанын талаптарына негизделген тууралуу төмөнгө көйгөй тантуу

- Көп берилүүчү суроолор (FAQ)

EN

EN