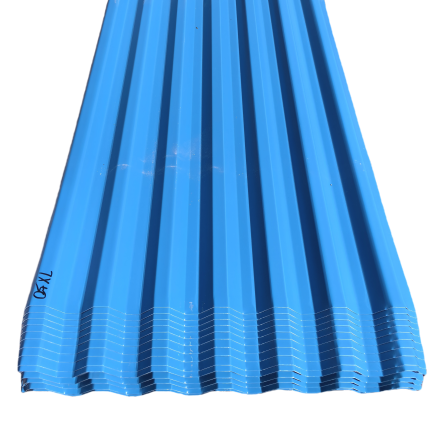

Les plaques d'acier jouent un rôle crucial dans les bâtiments à structure en acier. Elles agissent comme des éléments fondamentaux, garantissant la stabilité et la résistance de l'ensemble de la structure. Ces plaques répartissent les charges efficacement, empêchant la concentration de stress à des points spécifiques. Leur conception robuste améliore la durabilité des bâtiments, leur permettant de résister à une utilisation intensive et à des défis environnementaux. Les fonctions des plaques d'acier s'étendent également à la possibilité de concevoir des architectures innovantes, offrant une flexibilité pour les besoins de construction modernes. Leur polyvalence et leur fiabilité les rendent indispensables pour créer des structures sûres et durables.

Support structurel et répartition des charges

Les plaques d'acier servent de composants critiques dans les bâtiments à structure en acier, garantissant stabilité et résistance. Leur capacité à supporter une pression immense les rend indispensables dans la construction moderne. En comprenant les fonctions spécifiques des plaques d'acier, on peut apprécier leur rôle dans la création de structures sûres et durables.

Fonctions des plaques en acier dans le support de charges lourdes

Les plaques en acier excellent dans le support de charges lourdes en raison de leur haute résistance à la traction et de leur durabilité. Les ingénieurs comptent sur ces plaques pour supporter un poids significatif sans compromettre l'intégrité structurelle des bâtiments. Dans la construction, ils utilisent souvent des plaques en acier comme plaques de base, qui agissent comme fondation pour les colonnes en acier. Ces plaques répartissent la charge des colonnes uniformément sur la fondation en béton, empêchant la concentration de stress. Cette capacité garantit que les bâtiments peuvent résister à une utilisation intensive, comme dans les installations industrielles ou les grands espaces commerciaux.

Rôle dans la répartition du poids sur les poutres et les colonnes

Les fonctions des plaques d'acier vont au-delà du port de charge. Elles jouent un rôle vital dans la répartition du poids sur les poutres et les colonnes. Lorsqu'elles sont intégrées dans la structure, les plaques d'acier aident à répartir la charge uniformément, réduisant ainsi le risque de défaillance structurelle. Par exemple, les plaques de renfort relient les poutres et les colonnes, assurant la stabilité aux jonctions critiques. Cette distribution minimise le stress sur les composants individuels, améliorant la résilience globale de la structure. Ce faisant, les plaques d'acier contribuent à la longévité et à la sécurité des bâtiments en acier.

Applications dans les gratte-ciel et les grandes infrastructures

Les plaques d'acier trouvent des applications étendues dans les gratte-ciel et les grandes infrastructures Projets . Dans les gratte-ciels, ils fournissent le soutien nécessaire pour gérer les charges verticales et latérales causées par le vent et l'activité sismique. Leur utilisation dans les ponts et les installations industrielles met en évidence leur polyvalence. Par exemple, les plaques d'acier renforcent les tabliers de pont, garantissant qu'ils peuvent supporter de lourdes charges de trafic. Dans les bâtiments de grande hauteur, elles permettent la construction d'espaces ouverts en réduisant le besoin de colonnes internes excessives. Cette flexibilité permet aux architectes de concevoir des espaces innovants et fonctionnels tout en maintenant l'intégrité structurelle.

"Les plaques d'acier sont la colonne vertébrale de la construction moderne, permettant aux architectes et aux ingénieurs de repousser les limites du design et de la fonctionnalité."

Les fonctions des plaques d'acier dans ces applications démontrent leur importance dans la création de structures robustes et efficaces. Leur capacité à supporter de lourdes charges, à répartir le poids et à s'adapter à divers besoins architecturaux garantit leur pertinence continue dans l'industrie de la construction.

Renforcement et Stabilité

Les plaques en acier jouent un rôle essentiel dans le renforcement des bâtiments à structure en acier et garantissent leur stabilité. Leur capacité à renforcer les connexions, à prévenir la déformation structurelle et à améliorer la résistance aux séismes les rend indispensables dans la construction moderne.

Renforcement des connexions dans les structures en acier

Les plaques en acier améliorent la résistance des connexions dans les structures en acier. Les ingénieurs les utilisent pour relier solidement les poutres, les colonnes et d'autres composants structurels. Par exemple, les plaques de raccordement relient deux sections d'une poutre ou d'une colonne, garantissant un transfert de charges sans faille. Les plaques de renfort, une autre application courante, fournissent un soutien supplémentaire aux joints où plusieurs éléments se rencontrent. Ces plaques empêchent la formation de points faibles dans la structure, réduisant ainsi le risque de défaillance sous contrainte. En renforçant ces connexions critiques, les plaques en acier contribuent à la stabilité et à la sécurité globales du bâtiment.

Prévention de la déformation, de la flexion et du flambage

Les fonctions des plaques en acier s'étendent à la prévention de la déformation, du pliage et du flambage dans les structures en acier. La haute résistance à la traction permet à ces plaques de résister aux forces qui pourraient compromettre l'intégrité du bâtiment. Dans les zones soumises à des charges lourdes ou à des forces dynamiques, telles que les installations industrielles ou les ponts, les plaques en acier agissent comme des renforts. Elles répartissent le stress uniformément sur la structure, minimisant le risque de dommages localisés. Les ingénieurs intègrent souvent des plaques de raidissement dans les poutres et les colonnes pour maintenir leur forme sous pression. Cette approche garantit que la structure reste stable et fonctionnelle au fil du temps.

Utilisation de plaques en acier dans les conceptions résistantes aux tremblements de terre

Les plaques d'acier sont essentielles aux conceptions résistantes aux tremblements de terre. Leur capacité à absorber et à dissiper l'énergie lors des événements sismiques aide à protéger les bâtiments de l'effondrement. Les systèmes d'isolation de base incluent souvent des plaques d'acier pour réduire le transfert des mouvements du sol à la structure. Les murs de cisaillement renforcés avec des plaques d'acier améliorent la stabilité latérale, empêchant un balancement excessif lors des tremblements de terre. De plus, les ingénieurs utilisent des plaques d'acier pour renforcer les joints et les connexions, garantissant qu'ils restent intacts dans des conditions extrêmes. Ces applications soulignent l'importance des plaques d'acier dans la création de structures capables de résister aux catastrophes naturelles.

"L'incorporation de plaques d'acier dans les conceptions structurelles garantit la résilience face aux stress quotidiens et aux événements extraordinaires."

Le renforcement et la stabilité fournis par les plaques d'acier sont essentiels pour la longévité et la sécurité des bâtiments en acier. Leur capacité à renforcer les connexions, à résister à la déformation et à améliorer la résistance aux tremblements de terre souligne leur valeur dans les pratiques de construction modernes.

Flexibilité dans la conception et la personnalisation

Les plaques d'acier offrent une flexibilité inégalée dans la conception architecturale et la personnalisation. Leur adaptabilité permet aux architectes et aux ingénieurs d'explorer des possibilités créatives tout en maintenant l'intégrité structurelle. Cette polyvalence a fait des plaques d'acier un choix privilégié dans la construction moderne.

Polyvalence des plaques d'acier dans les applications architecturales

Les plaques d'acier offrent aux architectes la liberté de concevoir des structures qui allient fonctionnalité et esthétique. Leur capacité à supporter de grandes portées sans colonnes internes excessives permet de créer des intérieurs ouverts et spacieux. Cette caractéristique s'avère essentielle dans les bâtiments commerciaux, les musées et les aéroports où des agencements expansifs sont nécessaires. Les plaques d'acier contribuent également à des conceptions extérieures uniques, telles que des façades courbes ou des motifs géométriques complexes. Ces applications démontrent comment les plaques d'acier améliorent à la fois l'attrait visuel et la praticité des bâtiments.

"La polyvalence des plaques d'acier permet aux architectes de transformer des concepts ambitieux en réalité."

De plus, les plaques d'acier servent d'éléments décoratifs dans l'architecture de style industriel. Leur apparence élégante et moderne complète d'autres matériaux comme le verre et le béton, créant une esthétique contemporaine. Cette adaptabilité garantit que les plaques d'acier restent pertinentes dans divers styles architecturaux.

Personnalisation pour des exigences de conception spécifiques

Les plaques en acier peuvent être personnalisées pour répondre aux exigences uniques de tout projet. Les ingénieurs peuvent couper, façonner et souder ces plaques dans diverses tailles et formes, garantissant qu'elles s'intègrent parfaitement dans la conception. Par exemple, des plaques en acier découpées sur mesure sont souvent utilisées dans les ponts pour répondre à des exigences de charge spécifiques. Dans les immeubles de grande hauteur, des plaques en acier sur mesure renforcent des zones critiques, telles que les joints et les connexions, pour améliorer la stabilité.

La capacité de modifier les plaques en acier s'étend à leur épaisseur et à leurs traitements de surface. Des revêtements peuvent être appliqués pour améliorer la résistance à la corrosion ou obtenir une finition souhaitée. Ce niveau de personnalisation permet aux plaques en acier de s'adapter à différents environnements, des régions côtières aux zones industrielles. En adaptant les plaques en acier aux besoins spécifiques, les professionnels de la construction peuvent optimiser à la fois la performance et l'esthétique.

Intégration avec d'autres matériaux comme le verre et le béton

Les plaques d'acier s'intègrent parfaitement avec des matériaux comme le verre et le béton, permettant des techniques de construction innovantes. Dans les systèmes de murs-rideaux, les plaques d'acier fournissent le soutien nécessaire pour de grandes panneaux de verre, créant des façades transparentes qui maximisent la lumière naturelle. Cette intégration améliore l'efficacité énergétique et réduit le besoin d'éclairage artificiel.

Dans la construction composite, les plaques d'acier travaillent en tandem avec le béton pour former des structures hybrides. Par exemple, les plaques d'acier renforcent les dalles de béton dans les sols et les ponts, combinant la résistance de l'acier avec les propriétés de compression du béton. Cette synergie aboutit à des structures plus légères mais plus solides, réduisant l'utilisation de matériaux et les coûts de construction.

Les fonctions des plaques d'acier vont au-delà du soutien structurel. Leur compatibilité avec d'autres matériaux permet aux architectes d'expérimenter avec des textures, des couleurs et des finitions, réalisant des designs uniques. Cette intégration souligne l'importance des plaques d'acier dans la construction moderne, où l'innovation et l'efficacité vont de pair.

Durabilité et résistance aux facteurs environnementaux

Résistance à la corrosion grâce à des revêtements protecteurs

Les plaques d'acier démontrent une durabilité exceptionnelle, en particulier lorsqu'elles sont traitées avec des revêtements protecteurs. Les ingénieurs appliquent souvent des revêtements comme la galvanisation ou l'époxy pour protéger les plaques d'acier de la corrosion. Ces traitements créent une barrière qui empêche l'humidité et l'oxygène d'atteindre la surface de l'acier, réduisant ainsi le risque de formation de rouille. Dans les zones côtières ou industrielles, où l'exposition à l'eau salée ou aux produits chimiques est courante, ces revêtements prolongent considérablement la durée de vie des plaques d'acier.

"Les revêtements protecteurs garantissent que les plaques d'acier conservent leur intégrité structurelle, même dans les environnements les plus difficiles."

Un entretien régulier et une réapplication des revêtements renforcent encore la résistance à la corrosion. Cette approche proactive minimise les coûts de réparation et garantit la fiabilité à long terme des bâtiments en acier.

Résistance au feu et aux intempéries dans des conditions extrêmes

Les plaques d'acier présentent une résistance remarquable au feu et aux conditions météorologiques défavorables. Leur point de fusion élevé leur permet de résister à une chaleur extrême sans perdre leur intégrité structurelle. Les ingénieurs intègrent souvent des revêtements résistants au feu ou des peintures intumescentes pour améliorer cette propriété. Ces matériaux se dilatent lorsqu'ils sont exposés à la chaleur, formant une couche isolante qui retarde la propagation du feu. Cette caractéristique fournit un temps critique pour l'évacuation et réduit les dommages à la structure.

En plus de leur résistance au feu, les plaques d'acier supportent des conditions météorologiques difficiles, y compris de fortes pluies, de la neige et des vents violents. Leur composition robuste résiste à la déformation, aux fissures ou à la détérioration causée par les fluctuations de température. Cette résilience fait des plaques d'acier un choix fiable pour les bâtiments dans les régions sujettes à des événements météorologiques sévères.

Longévité des plaques d'acier dans des environnements difficiles

La longévité des plaques d'acier les distingue comme un matériau privilégié dans la construction. Leur capacité à résister à l'usure garantit qu'elles restent fonctionnelles pendant des décennies, même dans des environnements difficiles. Par exemple, dans les installations industrielles, les plaques d'acier supportent une exposition constante aux vibrations des machines lourdes et aux déversements chimiques. Dans les ponts, elles supportent des charges de trafic continues et des facteurs de stress environnementaux sans compromettre leur performance.

"La durabilité des plaques d'acier contribue à la durabilité des projets de construction en réduisant le besoin de remplacements fréquents."

Un bon design, une installation et un entretien appropriés prolongent encore la durée de vie des plaques d'acier. En investissant dans des matériaux de haute qualité et des mesures de protection, les professionnels de la construction s'assurent que les bâtiments en acier restent sûrs et efficaces au fil du temps. Cette durabilité souligne la valeur des plaques d'acier dans la création de structures qui résistent à l'épreuve du temps.

Rôle dans la construction modulaire et préfabriquée

Simplifier les processus de construction avec des composants préfabriqués

Les plaques d'acier jouent un rôle significatif dans la construction modulaire et préfabriquée en rationalisant les processus de construction. Les fabricants découpent et assemblent à l'avance les plaques d'acier en composants, réduisant ainsi le besoin de fabrication extensive sur site. Cette approche minimise les tâches intensives en main-d'œuvre sur les chantiers de construction, permettant aux travailleurs de se concentrer sur un assemblage efficace. Les composants en plaques d'acier préfabriquées garantissent également une qualité constante, car ils sont produits dans des conditions contrôlées en usine. Cette cohérence renforce l'intégrité structurelle des bâtiments et réduit la probabilité d'erreurs lors de l'installation.

L'utilisation de plaques d'acier préfabriquées accélère les délais de projet. Les équipes de construction peuvent assembler les modules rapidement, permettant une réalisation plus rapide des projets. Par exemple, dans des secteurs à forte demande comme le logement résidentiel ou les espaces commerciaux, cette rapidité s'avère inestimable. En simplifiant les processus de construction, les plaques d'acier contribuent à des pratiques de construction rentables et efficaces en termes de temps.

"Les composants en plaques d'acier préfabriqués révolutionnent la construction en combinant précision, efficacité et fiabilité."

Améliorer la durabilité grâce à la recyclabilité

Les plaques d'acier soutiennent la durabilité dans la construction en raison de leur recyclabilité. Contrairement à de nombreux autres matériaux, l'acier conserve ses propriétés même après plusieurs processus de recyclage. Cette caractéristique en fait un choix respectueux de l'environnement pour la construction modulaire et préfabriquée. Les constructeurs peuvent réutiliser des plaques d'acier provenant de structures mises hors service, réduisant ainsi la demande de matières premières. Cette pratique conserve les ressources naturelles et minimise l'impact environnemental des activités de construction.

Le recyclage des plaques d'acier réduit également la génération de déchets. Au lieu de jeter des matériaux anciens ou inutilisés, les fabricants peuvent les fondre et les réutiliser pour créer de nouveaux composants. Ce système en boucle fermée s'aligne sur les objectifs de construction durable, favorisant l'efficacité des ressources et réduisant les contributions aux décharges. En donnant la priorité à la recyclabilité, les plaques d'acier aident l'industrie de la construction à adopter des pratiques plus écologiques.

Réduction des déchets de matériaux et du temps de construction

Les plaques d'acier contribuent à la réduction des déchets en permettant une utilisation précise des matériaux. Les techniques de fabrication avancées permettent aux ingénieurs de couper les plaques d'acier aux dimensions exactes, minimisant les chutes et les déchets. Cette précision garantit que chaque pièce a une utilité, réduisant ainsi les déchets inutiles. Dans la construction modulaire, les composants en plaques d'acier préfabriqués optimisent encore l'utilisation des matériaux. Les usines produisent uniquement les quantités nécessaires, évitant ainsi la production excédentaire et l'excès d'inventaire.

Les avantages en termes de gain de temps des plaques en acier vont au-delà de la fabrication. Leur nature préfabriquée simplifie l'assemblage sur site, réduisant les retards causés par des installations complexes. Les travailleurs peuvent terminer les projets plus rapidement, respectant des délais serrés sans compromettre la qualité. Cette efficacité réduit les coûts de main-d'œuvre et améliore la productivité globale.

Les plaques en acier illustrent l'efficacité dans la construction en réduisant les déchets, en économisant du temps et en offrant des performances supérieures.

En intégrant des plaques en acier dans la construction modulaire et préfabriquée, les constructeurs atteignent un équilibre entre durabilité, efficacité et innovation. Ces avantages positionnent les plaques en acier comme une pierre angulaire des pratiques de construction modernes.

Les plaques d'acier jouent un rôle vital dans l'assurance de l'intégrité structurelle et de la stabilité des bâtiments en acier. Leur capacité à supporter de lourdes charges, à résister aux défis environnementaux et à s'adapter à des conceptions architecturales diverses souligne leur importance dans la construction moderne. Ces plaques améliorent l'efficacité en soutenant des pratiques de construction innovantes tout en maintenant la durabilité. À mesure que les méthodes de construction avancent, les fonctions des plaques d'acier continueront à favoriser des solutions durables et tournées vers l'avenir. Leur polyvalence et leur fiabilité solidifient leur position en tant que composants indispensables dans la création de structures sûres et durables.

EN

EN