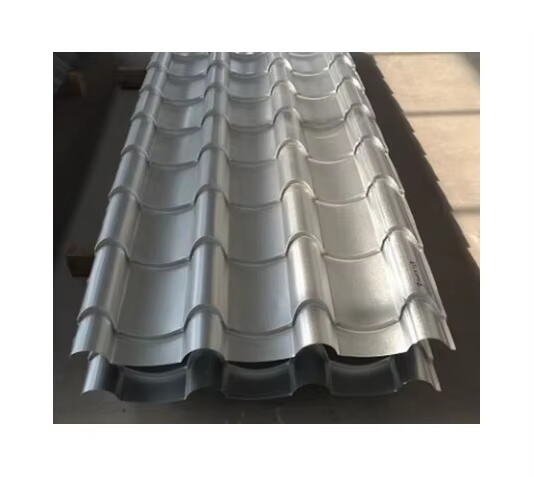

গ্যালভানাইজিং করুগেটেড শীটকে মরিচা এবং ক্ষয় থেকে রক্ষা করে, তাদের আয়ু বাড়ায়। জিঙ্কের আবরণ একটি ঢাল তৈরি করে যা আর্দ্রতা এবং ক্ষতিকারক রাসায়নিকগুলিকে ব্লক করে। এই সুরক্ষামূলক স্তর নিশ্চিত করে যে নিচের ধাতু অক্ষত থাকে। আপনি শক্তিশালী, দীর্ঘস্থায়ী শীটের সুবিধা পান যা কম রক্ষণাবেক্ষণের প্রয়োজন। গ্যালভানাইজিং প্রভাব এই শীটগুলিকে টেকসইতার জন্য একটি খরচ-কার্যকর পছন্দ করে তোলে।

গ্যালভানাইজিং কী এবং এটি কীভাবে কাজ করে?

গ্যালভানাইজিং প্রক্রিয়া ব্যাখ্যা করা হয়েছে

গ্যালভানাইজিং একটি প্রক্রিয়া যা ধাতব পৃষ্ঠকে মরিচা এবং ক্ষয় থেকে রক্ষা করে। এটি সাধারণত স্টীল বা লোহা ধাতুকে জিঙ্কের একটি স্তর দিয়ে আবৃত করার সাথে জড়িত। এই জিঙ্ক স্তর একটি ঢাল হিসাবে কাজ করে, ধাতুর নিচে আর্দ্রতা এবং অক্সিজেন থেকে রক্ষা করে। আপনি হয়তো ভাবছেন এই আবরণটি কিভাবে প্রয়োগ করা হয়। সবচেয়ে সাধারণ পদ্ধতি হল হট-ডিপ গ্যালভানাইজিং। এই প্রক্রিয়ায়, ধাতুকে প্রায় 860°F তাপমাত্রায় গলিত জিঙ্কে ডুবানো হয়। জিঙ্ক পৃষ্ঠের সাথে বন্ধন করে, একটি টেকসই এবং রক্ষাকারী স্তর তৈরি করে।

আরেকটি পদ্ধতি হল ইলেকট্রো-গ্যালভানাইজিং। এই প্রযুক্তিটি জিঙ্ক আবরণ প্রয়োগ করতে একটি বৈদ্যুতিক প্রবাহ ব্যবহার করে। যদিও এটি হট-ডিপ গ্যালভানাইজিংয়ের তুলনায় একটি পাতলা স্তর তৈরি করে, তবুও এটি কার্যকরী সুরক্ষা প্রদান করে। উভয় পদ্ধতি নিশ্চিত করে যে ধাতু কঠোর অবস্থাতেও দীর্ঘস্থায়ী হয়। এই প্রক্রিয়াটি বোঝার মাধ্যমে, আপনি দেখতে পারেন কিভাবে গ্যালভানাইজিং প্রভাব কোরুগেটেড শীটগুলির স্থায়িত্ব বাড়ায়।

ধাতু সুরক্ষায় গ্যালভানাইজিংয়ের উদ্দেশ্য

গ্যালভানাইজিংয়ের প্রধান উদ্দেশ্য হল মরিচা এবং ক্ষয় প্রতিরোধ করা। যখন ধাতু বায়ু এবং পানির সংস্পর্শে আসে, এটি মরিচা গঠনের জন্য প্রতিক্রিয়া করে, যা সময়ের সাথে সাথে কাঠামোকে দুর্বল করে। জিঙ্কের আবরণ এই প্রতিক্রিয়াকে একটি বাধা হিসেবে কাজ করে বন্ধ করে দেয়। এটি আর্দ্রতা, অক্সিজেন এবং অন্যান্য ক্ষতিকারক উপাদানগুলিকে ধাতুর কাছে পৌঁছাতে বাধা দেয়। জিঙ্কের স্তর যদি আঁচড়ে যায়, তবুও এটি একটি প্রক্রিয়ার মাধ্যমে ধাতুকে রক্ষা করে যা বলছে বলিদান সুরক্ষা। জিঙ্ক ধাতুর পরিবর্তে ক্ষয় হয়, নিশ্চিত করে যে কাঠামো শক্তিশালী থাকে।

এই সুরক্ষা গ্যালভানাইজড ধাতুকে বাইরের ব্যবহারের জন্য আদর্শ করে তোলে। আপনি যদি বৃষ্টি, আর্দ্রতা বা রাসায়নিকের সাথে মোকাবিলা করেন, তবে জিঙ্কের আবরণ নিশ্চিত করে যে ধাতুটি অক্ষত থাকে। গ্যালভানাইজড করুগেটেড শীটগুলি বেছে নিয়ে, আপনি একটি সমাধানে বিনিয়োগ করছেন যা ক্ষতির বিরুদ্ধে প্রতিরোধ করে এবং বছরের পর বছর স্থায়ী হয়।

গ্যালভানাইজিং করুগেটেড শীটগুলির স্থায়িত্বকে কীভাবে প্রভাবিত করে?

মরিচা প্রতিরোধে জিঙ্কের আবরণের ভূমিকা

জিঙ্ক আবরণটি তরঙ্গিত শীটগুলিকে মরিচা থেকে রক্ষা করতে একটি গুরুত্বপূর্ণ ভূমিকা পালন করে। যখন আপনি ধাতুকে বায়ু এবং আর্দ্রতার সম্মুখীন করেন, এটি অক্সিডাইজ হতে শুরু করে, মরিচা গঠন করে। এটি কাঠামোটিকে দুর্বল করে এবং এর আয়ু কমিয়ে দেয়। জিঙ্ক স্তরটি একটি শারীরিক বাধা তৈরি করে এর প্রতিরোধ করে। এটি অক্সিজেন এবং জলকে ধাতুর পৃষ্ঠে পৌঁছাতে বাধা দেয়। এই সুরক্ষামূলক ঢালটি নিশ্চিত করে যে আপনার তরঙ্গিত শীটগুলি বছরের পর বছর ধরে শক্তিশালী এবং কার্যকর থাকে। গ্যালভানাইজিং প্রভাবটি বিশেষত সেই পরিবেশে লক্ষ্যণীয় যেখানে মরিচা দ্রুত গঠন করে, যেমন উপকূলীয় এলাকা বা উচ্চ আর্দ্রতা সহ অঞ্চল।

গ্যালভানাইজিং কীভাবে আর্দ্রতা এবং রাসায়নিকের বিরুদ্ধে একটি বাধা হিসাবে কাজ করে

গ্যালভানাইজিং একটি টেকসই বাধা তৈরি করে যা আর্দ্রতা এবং ক্ষতিকারক রাসায়নিকের বিরুদ্ধে প্রতিরোধ করে। যখন জল বা রাসায়নিকগুলি জিঙ্ক আবরণে যোগাযোগ করে, তখন সেগুলি প্রবাহিত হতে পারে না। এটি নীচের ধাতুকে ক্ষতির থেকে রক্ষা করে। আপনি এই বৈশিষ্ট্যটি বিশেষভাবে শিল্প বা কৃষি পরিবেশে উপকারী পাবেন যেখানে রাসায়নিকের সংস্পর্শ সাধারণ। জিঙ্ক স্তরও কঠোর আবহাওয়ার অবস্থার বিরুদ্ধে প্রতিরোধ করে, গ্যালভানাইজড করুগেটেড শীটগুলি বাইরের ব্যবহারের জন্য আদর্শ করে তোলে। গ্যালভানাইজড শীটগুলি নির্বাচন করে, আপনি পরিবেশগত উপাদানের বিরুদ্ধে দীর্ঘমেয়াদী সুরক্ষা নিশ্চিত করেন।

ত্যাগী সুরক্ষার পিছনের বিজ্ঞান

বলিদান সুরক্ষা হল আরেকটি উপায় যা গ্যালভানাইজিং স্থায়িত্ব বাড়ায়। এমনকি যদি জিঙ্কের আবরণ আঁচড়ানো বা ক্ষতিগ্রস্ত হয়, তবুও এটি ধাতুকে সুরক্ষিত রাখতে থাকে। জিঙ্ক স্টিল বা লোহা থেকে বেশি প্রতিক্রিয়াশীল। ক্ষয়কারী উপাদানের সংস্পর্শে আসলে, জিঙ্ক প্রথমে ক্ষয় হয়, নিচে থাকা ধাতুকে অক্ষত রেখে। এই প্রক্রিয়া নিশ্চিত করে যে আপনার ঢেউখেলানো শীটগুলি অক্ষত থাকে, এমনকি চ্যালেঞ্জিং অবস্থাতেও। গ্যালভানাইজিং প্রভাব আপনার শীটগুলির আয়ু বাড়ানোর জন্য একটি নির্ভরযোগ্য সমাধান প্রদান করে, এমনকি যখন সামান্য ক্ষতি ঘটে।

গ্যালভানাইজিংয়ের সুবিধা ঢেউখেলানো শীটের জন্য

বাড়তি স্থায়িত্ব এবং ক্ষয় প্রতিরোধ

গ্যালভানাইজিং তরঙ্গিত শীটগুলিকে শক্তিশালী করে, তাদের মরিচা এবং ক্ষয় প্রতিরোধী করে। দস্তের আবরণ ধাতুকে আর্দ্রতা এবং অক্সিজেন থেকে রক্ষা করে, যা মরিচার প্রধান কারণ। এই সুরক্ষা নিশ্চিত করে যে আপনার শীটগুলি চ্যালেঞ্জিং পরিবেশেও অক্ষত থাকে। সময়ের সাথে সাথে, অপ্রক্রিয়াকৃত ধাতু দুর্বল হয়ে যায় এবং এর কাঠামোগত অখণ্ডতা হারায়। তবে গ্যালভানাইজড শীটগুলি বছরের পর বছর তাদের শক্তি বজায় রাখে। আপনি এই স্থায়িত্বের উপর নির্ভর করতে পারেন, বাড়ি এবং শিল্প উভয় ক্ষেত্রেই। গ্যালভানাইজিং প্রভাব নিশ্চিত করে যে আপনার শীটগুলি কার্যকর এবং নির্ভরযোগ্য থাকে, এমনকি উচ্চ আর্দ্রতা বা ঘন বৃষ্টিপাতের এলাকায়ও।

রক্ষণাবেক্ষণ এবং মেরামতের খরচ কমানো

গ্যালভানাইজড করুগেটেড শিট ব্যবহার করে আপনি পয়সা বাঁচাতে পারেন কারণ এটি রক্ষণাবেক্ষণ এবং মেরামতের প্রয়োজন কমায়। জিংক কোটিংग ক্ষতি রোধ করে, তাই আপনাকে নিয়মিত জোঁক দূর করা বা মেরামতের সমস্যায় পড়তে হবে না। এর ফলে শিটের জীবনকালের মধ্যে খরচ কম হবে। আপনি ক্ষতিগ্রস্থ উপাদান প্রতিস্থাপনের অসুবিধাও এড়াতে পারেন। গ্যালভানাইজড শিট নির্বাচন করে আপনি একটি দীর্ঘমেয়াদি সমাধানে বিনিয়োগ করছেন যা রক্ষণাবেক্ষণ কমিয়ে দেয়। এটি দুর্ভেদ্যতা এবং কম রক্ষণাবেক্ষণের প্রয়োজনীয়তা থাকা প্রকল্পের জন্য লাগসটিক-এফেক্টিভ বিকল্প।

কঠোর পরিবেশ এবং বাইরের ব্যবহারের জন্য উপযুক্ত

গ্যালভানাইজড শীটগুলি কঠোর অবস্থায় অসাধারণভাবে কাজ করে। ভারী বৃষ্টির, তুষারের বা রাসায়নিকের সংস্পর্শে আসা হলে, জিঙ্কের আবরণ নিচের ধাতুকে রক্ষা করে। এটি তাদের বাইরের ব্যবহারের জন্য আদর্শ করে, বিশেষ করে শিল্প বা কৃষি পরিবেশে। আপনি উপকূলীয় এলাকায় ব্যবহার করতে পারেন যেখানে লবণাক্ত জল ক্ষয়কে ত্বরান্বিত করে। চরম আবহাওয়া সহ্য করার তাদের ক্ষমতা নিশ্চিত করে যে তারা বছরের পর বছর একটি নির্ভরযোগ্য পছন্দ হিসেবে থাকে। গ্যালভানাইজিং প্রভাবের সাথে, আপনি একটি পণ্য পান যা কঠোর পরিবেশে মানের সাথে আপস না করে কাজ করে।

গ্যালভানাইজিং আপনার করুগেটেড শীটগুলিকে মরিচা এবং পরিবেশগত ক্ষতি থেকে রক্ষা করে। জিঙ্কের আবরণ স্থায়িত্ব নিশ্চিত করে এবং রক্ষণাবেক্ষণের খরচ কমায়। আপনি দীর্ঘমেয়াদী ব্যবহারের জন্য একটি খরচ-কার্যকর সমাধান পান, বিশেষ করে কঠোর অবস্থায়। গ্যালভানাইজিং প্রভাব এই শীটগুলিকে একটি ব্যবহারিক পছন্দ করে তোলে যিনি নির্ভরযোগ্য, দীর্ঘস্থায়ী উপকরণ খুঁজছেন যা চ্যালেঞ্জিং পরিবেশে ভাল কাজ করে।

EN

EN